Innovation and circular economy in Wastewater Treatment Plants: Challenges and Barriers

The water system is a part of environmental, agricultural, industrial, and municipal systems. Knowing how these systems are connected to each other is critical for the identification of circular economy opportunities that exist within the water system and other associated systems as well.

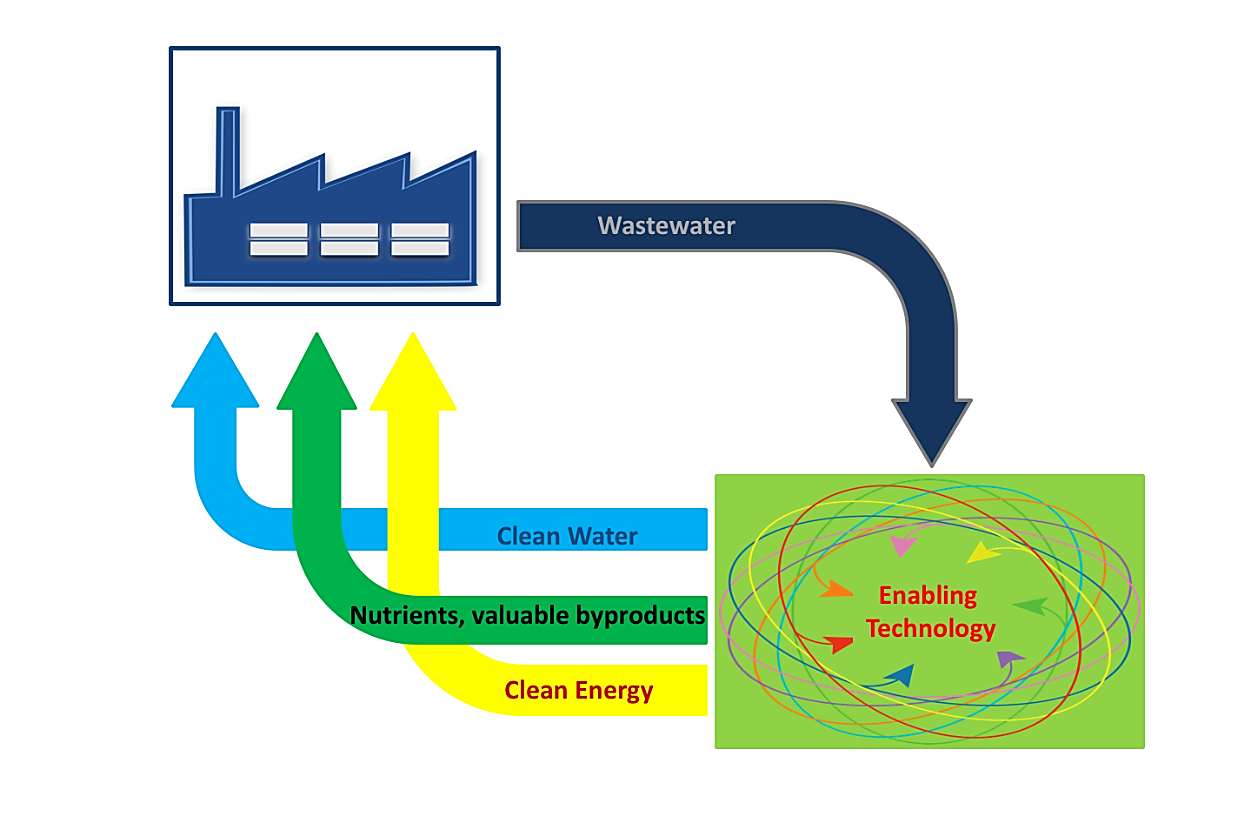

The wastewater treatment plants (WWTPs) can be an important part of circular sustainability due to integration of energy production and resource recovery during clean water production [2, 3]. In the near future, WWTPs will become “ecologically sustainable” technological systems. Currently, global nutrient needs and recovery of water and energy from wastewater dictate the development of the wastewater industry [4-6]. This Figure from Cerahelix.com shows the water cycle in a circular economy model:

To meet the challenge of reducing wastewater pollution ahead of population growth, changes in industrial processes, and technological developments, the US Environmental Protection Agency (US EPA) created a document to make information on recent advances and innovative techniques available for everyone [7]. The goal of the document is straightforward: to provide a guide for individuals seeking information on innovative and emerging wastewater treatment technologies. The guide lists new technologies, assesses their merits and costs, and provides sources for further technological investigation. This document should serve as a guideline for wastewater facility owners/utilities, operators, planners, and consultants.

In the next sections, we present the most important resources that can be obtained from WWTPs and the possibilities for entrepreneurs, whilst we show the strengths and weaknesses of these processes.

3.1 Land application of biosolids

Biosolids (sewage sludge) are made of compounds valuable for agricultural use (organic matter, nitrogen, phosphorous, potassium and micro‐nutrients such as calcium, sulphur and magnesium), and pollutants that include heavy metals, organic compounds, and pathogens. While they can be a valuable resource, they need to be used with caution. They often contain microorganisms that can carry diseases, chemical contaminants, or other unstable substance.

Biosolids can enrich the soil and supplement or replace commercial fertilizers. Biosolids land application occurs at various sites including agricultural lands, forests, mine reclamation sites, and other lands, parks, and golf courses. Land application of biosolids has significantly positive effects on soil fertility ensuring their use in a more sustainable manner. In addition to high nutritional value, biosolids improve the properties of the soil (soil conditioning) by increasing soil organic matter, soil particle aggregation, soil structure and porosity, and decreasing bulk density.

Land application of sewage sludge is widely practiced in Europe and other countries [8]. The risk associated with land application of biosolids depends on the origin of the pollution loads that enter the wastewater treatment plants (municipal versus industrial loads). The main problems associated with such biosolids disposal are the health and safety issues, odour, nuisance, and other public concerns. In addition, excessive rates of land application can negatively impact groundwater quality because of nutrient leaching. For that reason, US EPA has developed a guide for land appliers based on the federal standards for the use or disposal of sewage sludge. The intent of this federal programme is to ensure that sewage sludge is used or disposed of in a way that protects both human health and the environment. Part 503, Standards for the Use or Disposal of Sewage Sludge establishes the general requirements, pollutant limits, operational standards, and management practices, as well as frequency of monitoring, recordkeeping, and reporting requirements, for sewage sludge that is land applied, placed on a surface disposal site, or fired in a sewage sludge incinerator [9].

Treatments required before Land application of biosolids

To comply with the rules proposed by the legislation, sewage sludge has to be treated at the WWTPs (dewatered and stabilized) before land application either in terms of soil fertilization or land reclamation. The biosolids treatment processes before their application to the soil are anaerobic or aerobic digestion, composting, drying and chemical treatment (mostly alkaline treatment).

- Anaerobic digestion (in general) is a naturally occurring biological process in which large numbers of anaerobic bacteria convert organic matter into methane and carbon dioxide (a mixture called biogas). This process stabilizes the organic matter in wastewater solids, reduces pathogens, and odours, and reduces the total solids/sludge quantity by converting parts of the volatile solids (VS) fraction to biogas.

- Anaerobic digestion. The process can be divided into three separate steps, each of which is performed by a different group of microorganisms:

- Hydrolysis, during which the proteins, cellulose, lipids, and other complex organics are broken down into smaller molecules and become soluble by utilising water to split the chemical bonds of the substances

- Volatile acid fermentation, during which the products of hydrolysis are converted into organic acids through the biochemical processes of acidogenesis (where monomers are converted to fatty acids) and acetogenesis (the fatty acids are converted to acetic acid, carbon dioxide, and hydrogen)

- Methane formation, during which the organic acids produced during the fermentation are converted to methane and carbon dioxide.

- Composting wastewater residue is a bio-thermal aerobic process that decomposes the organic portion of residue by approximately 25 percent. Before composting, it is necessary to dewater the residue. Dewatering not only reduces the volume of the surplus but also decreases the amount of moisture that will evaporate during the heat generated by the decomposition of the organic portion of the residue, it also stabilises it and transforms the excess into usable biosolids. The problem with composting raw residuals is the more intense odour of the residuals with higher percentage of organic material. Various methods can be used to control the odour. In general, the odour is controlled by adding quick lime (CaO) to change the pH of the residuals. If odour continues to be a problem, the simple procedure of drawing air through the compost piles and discharging the air to a bio-filter can further reduce the odour.

- The type and population of microorganisms varies during the composting process. Therefore, it is critical to control the composting environment so that the microorganisms can thrive. The composting environment parameters include the compost pile temperature, moisture content of the compost, oxygen and carbon dioxide levels in the compost pile, and the availability of nutrients including carbon, nitrogen, phosphorus, and potassium for the microorganisms. These parameters must be monitored as they affect the vitality of the microorganisms. Oxygen is supplied to the compost pile by the introduction of air. The rate of air supplied depends on the moisture content of the compost pile. The higher the moisture content the higher rate of air is required. A minimum oxygen level must be maintained while carbon dioxide levels must not be allowed to exceed a maximum level.

Source: https://pixabay.com/images/search/sewage%20sludge%20composting/

3.2 Nutrient Recovery

Nutrient recovery is the practice of recovering nutrients such as nitrogen and phosphorus from used water streams that would otherwise be discarded and converting them into an environmentally friendly fertilizer for ecological and agricultural purposes. This process helps clean the effluent by removing these nutrients and ultimately transforming them into an efficient, reusable feedstock. With these objectives in mind, different processes have been developed in the wastewater industry to optimally recover these nutrients.

The recovery process of nutrients offers municipalities an opportunity to generate revenue while providing agricultural businesses with refined, usable phosphorus – an increasingly scarce natural resource. Moreover, it enables wastewater entities to serve as more than just treatment facilities but ultimately as resource recovery agents, transforming the perception of traditional wastewater treatment. Thus, nutrient recycling from WWTPs has positive impact on environment by reducing the demand of conventional fossil-based fertilizers and consequently, reducing the consumption of water and energy.

Recovery of nutrients from wastewater can be done from raw wastewater, semi-treated wastewater streams, and sewage sludge (biosolids) [10].

Currently, phosphorus (P) is recycled at WWTPs mainly by chemical methods like the struvite crystallisation process e.g., Pearl, NuReSys, and AirPrex technologies, which have been implemented at full-scale [11]. At present, in Europe more than 2000 Mg P/year are technically recovered [12]. The main problems associated with struvite crystallisation are the high chemical costs and unintentional struvite formation which blocks the valves, pipes, pumps etc. Even though the high operation costs limit the economic feasibility of nutrient recovery, the system could generate a wide range of other benefits. For example, the nutrient recovery from wastewater could substantially reduce the production of sludge and undesired precipitates, so the disposal costs related to the unexpected substances may be better controlled or even lowered. Also, the nutrient recovery from wastewater could improve dewatering treated sludge and decrease the scaling speed rate, both of which result in the improvement of wastewater management [14]. Evidently, nutrient recovery could also reduce the concentration of ammonium and phosphate in the discharge generated by a wastewater treatment plant, which prevents eutrophication in aquatic environments. However, both environmental benefits and government regulations would not serve to trigger nutrient recovery if there are insufficient economic incentives.

New technologies in Nutrient Recovery

Ye et al. 2020 pointed out that Microbial fuel cells (MFC), as an advanced technology for nutrient recovery, could generate electricity and offer high pH zone for chemical precipitation [15]. The technology is quite promising for recovering nutrients. Thus, the MFC and its modifications should be widely explored to recover nutrients in wastewater treatment.

In this scenario, forward osmosis (FO), membrane distillation (MD) and electrodialysis (ED) processes are the three main membrane technologies employed for the nutrients recovery. MD and ED process are compatible with MFCs while applying MFCs to recover nutrients from diluted wastewater. Such integration could undoubtedly increase the quality and quantity of recovered nutrients and is viable in the future. Another important aspect is to increase the anaerobic release of phosphate in the existing tanks in sufficient amounts [16]. In addition, feed solution’s property can determine the performance of membrane bioreactor by exerting direct impact on sludge properties, membrane fouling and permeate flux [17]. However, the role of feed solution in OMBR systems has not been analysed enough. It is necessary to conduct further studies to evaluate the feasibility of different wastewater sources with reference to the nutrient recovery and propose the appropriate pre-treatment for feed solution if necessary. In this case, the technical feasibility of the nutrient recovery system as well as its performance can be enhanced.

In the future, it can be expected that new research leads to further development of economical wastewater treatment systems, and osmotic membrane bioreactors (OMBR) and bioelectrochemical systems (BES) based hybrid systems in particular.

This can create new opportunities for entrepreneurs and start-ups.

3.3 Reclaimed water

Why reuse treated wastewater?

Only 2.5% of the water available on the planet is fresh water. With the rapid increase in the world population, the acceleration of urbanization and global warming, this resource is becoming scarce. Water over-abstraction is a major cause of water scarcity. Main pressures from water consumption are concentrated on irrigation and domestic demand, including tourism. Using treated wastewater reuse as an alternative source of water supply is now well acknowledged by international, European and national sustainability strategies. UN Sustainable Development Goal on Water (SDG 6) specifically targets substantial increase in recycling and safe global reuse by 2030. Water reuse is a top priority in the Strategic Implementation Plan of the European Innovation Partnership on Water, and maximisation of water reuse is a specific objective set in the Communication “Blueprint to safeguard Europe’s water resources”. Reuse of treated wastewater can provide significant environmental, social, and economic benefits. According to the Blueprint, water reuse can improve the status of the environment both quantitatively and qualitatively, alleviating pressure by substituting abstraction. Compared to alternative sources of water supply such as desalination or water transfer, water reuse often requires lower investment costs and energy, reducing greenhouse gas emissions.

Water reuse benefits the broader water sector which is a key component of EU eco-industrial landscape. Water reuse has significant potential in terms of the creation of green jobs in the water-related industry, and it is estimated that a 1% increase of the growth rate in the EU water industry could create up to 20.000 new jobs [18]. Currently, the amount of treated urban wastewater reused annually accounts for approximately 2.4% of the treated urban wastewater effluents and less than 0.5% of annual EU freshwater withdrawals. But the EU potential is much higher, estimated in six times the current volume. Both southern Member States such as Spain, Italy, Greece, Malta, and Cyprus and northern Member States like Belgium, Germany already have in place numerous initiatives regarding water reuse for irrigation, industrial uses, and aquifer recharge. Cyprus and Malta already reuse more than 90% and 60% of their wastewater respectively, while Greece, Italy, and Spain reuse between 5 to 12% of their effluents, which clearly indicates a potential for further uptake.

The reuse of treated wastewater from WWTPs for agriculture and land irrigation, industrial purposes, toilet flushing, and groundwater replenishing is key element of currently implemented strategy focused on releasing freshwater for domestic use, improvement the WWTPs effluent quality and consequently higher quality of river waters used for abstraction of drinking water [19]. The use of treated wastewater for irrigation in agriculture has been known for many years and can provide water supply to replace of the agriculture demand and reduction of local water stress. In addition, nutrients contained in the wastewater reduce the need for application of commercial fertilizers. It is recommended to use effluent from secondary treatment to irrigation of non-food crops while effluent from tertiary treatment for irrigation of food crops.

Urban wastewater reuse may be planned (direct or indirect) or unplanned which is mostly connected with non-potable uses, however there are cases of unplanned potable reuse. Urban water reuse concerns mainly residential irrigation and commercial use for fire protection, car wash, toilet flushing, etc. The main problems associated with urban reuse are: risks to human health and high cost of dual systems for the reclaimed water delivery [20]. In indirect potable reuse high quality WWTP effluent is discharged directly into groundwater or surface water sources with the intent of augmenting drinking water supplies. Another solution can be direct potable reuse (pipe to pipe) by directly introduction of treated wastewater into a water distribution system [21].

However, direct potable reuse strongly increases operational cost due to very high effluent quality requirements. The lack of social acceptance is also important.

Source: https://pixabay.com/images/search/water%20garden/?pagi=2

Reclaimed water for industrial processes

Depending on water quality requirements, space constraints, and budgetary considerations, various methods for recycling or reusing industrial water are available. Benefits can include the reduction of freshwater costs, wastewater flows, and the size of the water footprint. Operational efficiency and sustainability can also be increased along with the improved production capacity due to the increase in available clean water.

Technologies

From the perspective of wastewater treatment, microfiltration (MF), ultrafiltration (UF), nanofiltration (NF), and reverse osmosis (RO) are the most common membrane separation techniques applied in the industries. Forward osmosis (FO) has also been recently introduced as an advanced membrane technique for wastewater treatment. A range of other advanced water purification technologies, including activated carbon, ion exchange, deionisation, electro-deionisation, UV (ultra-violet), ozone disinfection, and chemical dosing are used for industrial application.

In wastewater treatment, membrane technology has been recognized as the key technology for the separation of contaminants from polluted sources [22]. Membranes are selective barriers that separate two different phases, allowing the passage of certain components and the retention of others. The agent that initiates membrane processes can be a pressure gradient and chemical or electrical potential across the membrane. Membrane processes depend on a physical separation, usually with no phase change and chemicals addition in the feed stream, thus stand out as an alternative wastewater treatment technique to conventional processes (i.e., distillation, precipitation, coagulation/flocculation, adsorption by active carbon, ion exchange, biological treatment, etc.) [22, 23]. The low energy consumption, reduction in number of processing steps, greater separation efficiency, and higher final product quality are the main advantages of these processes [22–24]. However, limited chemical, mechanical, and thermal resistance of the membranes restricts their application. Great efforts have been implemented to improve both flux and selectivity of the membranes. Furthermore, some researchers have focused on controlling membrane fouling, which is the most important problem in application of membranes in wastewater treatment. As a result, the performance has significantly increased, and commercial markets of membranes have been expanding during the past years.

The success of membrane operations in wastewater treatment is attributed to compatibility between different operations in integrated systems. The wastewater treatment by integrated systems nowadays suggests reducing environmentally harmful effects, decreasing groundwater and energy consumption, and recovering valuable compounds as a by-product. Membrane bioreactor (MBR), combining membrane filtration with biologic treatment, is recognised as one of the most successful hybrid membrane systems in wastewater treatment.

Pressure-driven membrane operations, MBRs, as well as a combination of membrane operations in hybrid systems in the treatment of wastewater are used in various industries.

Reclaimed water for irrigation

Agriculture is by far the largest global water consumer. Irrigation of agricultural lands accounted for 70% of the water used worldwide. In several developing countries, irrigation makes up to 95% of all water uses, and plays a major role in food production and food security. Future agricultural development strategies of most of these countries depend on the possibility to maintain, improve, and expand irrigated agriculture.

Water reuse is commonly and successfully practiced in several EU Member States, as well as in, for example, Israel, California, Australia, and Singapore. However, this practice is so far deployed below its potential in the EU. Limited awareness of potential benefits among stakeholders and the general public, and a lack of a supportive and coherent framework for water reuse were identified as two major barriers preventing a wider spreading of this practice in the EU. For these reasons, the Commission proposed in 2018 a regulation to boost water reuse when it is cost-efficient and safe for health and the environment.

The new Regulation on minimum requirements for water reuse for agricultural irrigation has recently entered into force and is expected to stimulate and facilitate water reuse in the EU [25]. The Commission has prepared also different key documents that can be found at ec.Europa.eu [18].

Potential pathogens have to be removed from wastewater. When pathogenic organisms are not specifically processed during treatment, the use of treated wastewater should be carefully evaluated. Different parameters affect the efficient removal of pathogenic and indicator microorganisms [26]. The evaluation of technologies for pathogen removal is mostly based on faecal contamination indicators, such as total coliforms, thermo-tolerant coliforms or Escherichia coli. Chlorine, ultra-violet (UV), ozone, maturation ponds, CW, membrane filtration, deep bed filtration, and electrochemical methods are techniques being used for disinfection [26]. When it comes to using oxidants for disinfection, sodium hypochlorite (NaClO), and ozone, several example practices can be found in literature related to reclamation systems for irrigation. Ultraviolet treatment is recommended by several guidelines as the best available technology for disinfection of reclaimed water that is not associated with excessive costs, in particular for high to medium contact reuse applications [26]. Regarding biological treatment, maturation ponds are considered to be the best practice of several guidelines, including WHO, [27]. This method has some advantages and disadvantages. More information can be found at TheWaterTreatments.com [28]

As an alternative to bed filtration and chemical treatment, membrane filtration is a technology often considered effective for removing pathogens from wastewater used in irrigation. The results indicate that a complete reduction of viruses is possible with an Ultra Filtration (UF) membrane, meaning that a chemical disinfection process could be omitted [27].

Endocrine-disrupting chemicals (EDCs) have been receiving increased attention in recent years due to their harmful effects on humans and animals. The presence of EDCs in irrigation water and agricultural soils can cause contamination of agricultural products, posing a risk to human health. New technologies for removing EDCs from wastewater entail new opportunities for entrepreneurs and start-ups.

Source: https://pixabay.com/images/search/agriculture%20water/?pagi=2

3.4 Energy Recovery

Energy recovery at wastewater treatment plants represents an important policy lever for sustainability since it can significantly decrease the carbon footprint of wastewater treatment. Wastewater treatment requires significant energy consumption. An analysis of the chemical and heat energy contained in wastewater reveals that there is up to 14 times more energy than what is required for treatment. Although much of this is low-grade heat, it should still be theoretically possible to achieve energy positivity in treatment plants.

In WWTPs, energy recovery can be done through [29-30]:

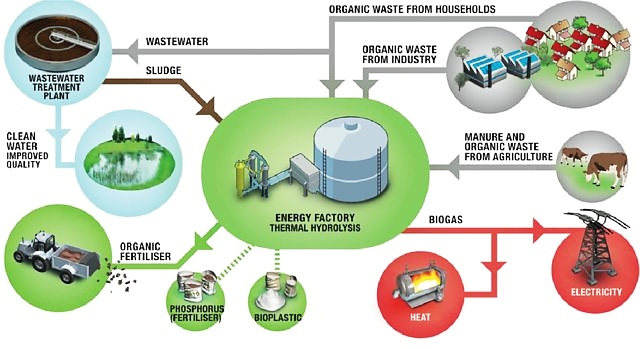

- Biogas production. In a digester via anaerobic digestion (AD) biogas is created, which is the main energy source in WWTP. The biogas can be used for heating and/or electricity generation. Enhancement of AD efficiency is a common practice to increase the energy self-sufficiency of WWTPs.

- Heat pumps in treatment plant effluents, and

- Energy recovery from various high temperature streams by heat exchanger

The optimisations of AD include different pre-treatment methods of sewage sludge aiming at higher biodegradability of sludge. Currently the most common technologies available on the market are mechanical and thermal pre-treatments. Thermal hydrolysis (THP) technologies like Cambi, Biothelys, Exelys are the most common technologies used to improve anaerobic digestion in WWTPs. The first WWTP in North America (Washington, DC, USA) that used Cambi technology saw a 50% increase in biogas production. Co-digestion of sewage sludge with other biodegradable waste is another option, which provides a range of economic and environmental benefits. Co-digestion of organic waste in combination with sewage sludge does not only allow WWTPs to be energy-neutral but also reduce the cost of municipal and industrial organic waste management. For example, co-digestion of sewage sludge with six different co-substrates has been implemented in Mossberg (Germany) for 10 years. The heat and energy production at Mossberg WWTP is significantly higher than the internal demand of WWTP. Excess energy is fed into the grid, while excess heat is used to dry dewatered sludge from other WWTPs.

Technologies used the most by existing self-sufficient WWTPs are “Combined Heat and Power (CHP)” technologies, which generate both electricity and heat from biogas at the same time. Reliable and economical sources of heat for use in heat pumps (HP) are the effluents from municipal WWTPs plants [31]. The heat from HPs can be used for heating and cooling of residential, social, and administrative buildings of the plant and/or neighbouring infrastructure.

In the Danish city of Odense, a treatment plant supplies heat and electrical energy for a population of almost 400,000 and has achieved 150 percent energy positivity, thus generating electricity and heat for the local grid. The transformation was made possible by a careful analysis of historical operational data which identified a series of energy optimization options, many of which were implemented with modifications in operational strategies rather than significant equipment upgrades. Since making the initial changes, a number of facility improvements were implemented that so that 200% energy positivity has been achieved. The technical interventions were grounded on the adoption of a very clear ‘carbon neutrality’ mindset across the organisation, which in turn led to the development and commitment to a very aggressive corporate environmental target [32].

Deutsch

Deutsch Español

Español Italiano

Italiano Nederlands

Nederlands Polski

Polski Română

Română