Circular economy and Wastewater Treatment Plants

The ‘Agenda: 2030’ of the United Nations has defined universal access to clean water as one of the Sustainable Development Goals and encourages governments to establish wastewater treatment plants (WWTPs) to improve the quality of water and ensure access to drinking water for people facing severe water-related issues. Water resources across the globe are getting increasingly polluted due to the lack of strict regulations on industries for waste disposal. Industries and factories that dispose industrial waste, heavy metals, dye, organic matter, bacteria, and toxic material into water resources are further polluting the water.

Principles of circular economy

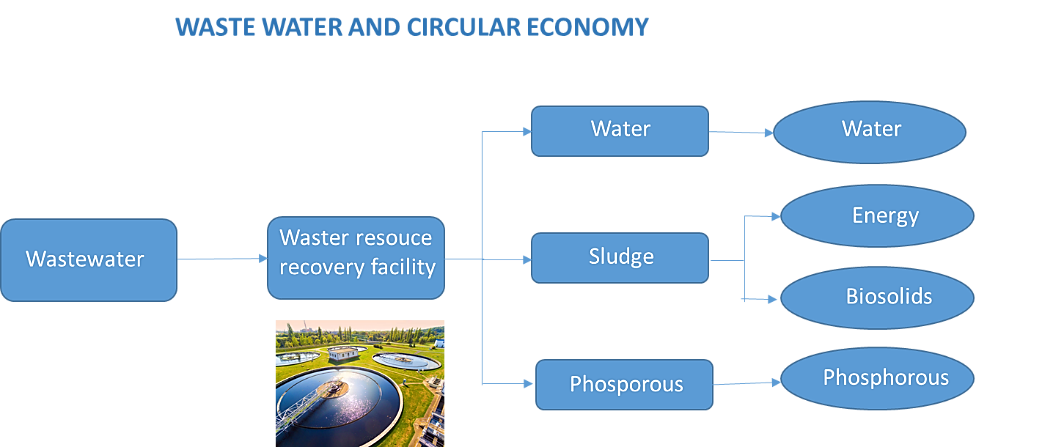

To consider any initiative related to the circular economy, it is necessary to point out the correlation between circular economy and wastewater treatment. To help entrepreneurs focus on transitioning to a circular economy and develop solutions with water systems experts, there must be a common understanding of key concepts.

Circular economy consists of activities that preserve value in the form of energy, labor, and materials. Circular economy mainly emerges through three main “actions”, i.e. the so called 3R’s Principles: Reduction, Reuse, and Recycle.

- The Reduction principle aims to minimize the input of primary energy, raw materials, and waste by improving efficiency in production (so called eco-efficiency) and consumption processes e.g. introducing better technologies in WWTP.

- The Reuse principle refers to “any operation by which products or components are used again for the same purpose for which they were conceived”. For example, water shortages in arid and semi-arid regions have led to the reuse of water as an alternative water supply in some parts of the world.

- The Recycle principle refers to “any recovery operation by which waste materials are reprocessed into products, materials or substances whether for the original or other purposes. For example, recycling WWTP sludge offers the opportunity to benefit from still usable resources and reduce the amount of waste that needs to be treated and/or disposed of, thus also reducing the related environmental impact.

Within the WWTP framework, three additional principles developed by the Ellen MacArthur Foundation [1] can be added to the 3R principles:

- The Proper Design highlights the importance of the design stage in finding solutions to avoid waste and contamination. This principle is applied in WWTPs optimizing the amount of energy, minerals and chemicals used in the operating systems.

- Keeping resources in use means optimising the performance of resources of the WWTPs (use and reuse of water, energy, recovery of nutrients and chemicals). For instance:

- Energy or resource extraction optimisation from the water system,

- Maximisation of its reuse. According to current national legislations around the world, the reuse purposes are varied – ranging from agricultural, industrial, urban, recreational, environmental, to even human consumption. At present, approximately 80% of wastewater is discharged into the world’s waterways without any kind of treatment.

- Optimisation of the value generated in the interfaces of water system (valorisation of sewage sludge) with other systems as agriculture and other uses,

- Recovery of nutrients from wastewater and their use as fertilizers.

- Regeneration of natural capital – This principle is based on the fact that we not only have to protect, but actively improve the environment. What we need to do is to:

- Preserve and enhance the natural capital (e.g. pollution prevention, quality of effluent, etc.), and

- Ensure minimum disruption to natural water systems from human interactions and use.

Source: Own illustration

2.1 Which are the main wastewater treatment processes?

Wastewater treatment is the procedure whereby water is processed in a manner so that it can be directly reused or discharged into the water cycle with minimal negative impact on the environment. Wastewater is full of contaminants including bacteria, chemicals, and other toxins. Its treatment aims at reducing the contaminants to acceptable levels to make the water safe for discharge back into the environment. The processes for wastewater treatment are as follows:

Physical/Chemical Treatment Processes

Physical processes remove solids from wastewater as it flows through screens (or filter media), or solids are removed by gravity settling or air flotation. Particles are then entrapped to the surface and can be removed. Chemicals can also be used in wastewater treatment to create changes in the pollutants that increase the ability to remove them. Changes may lead to substances forming floc or a heavier particle mass to make the removal by physical processes easier. The sludge – the solid waste that settles at the surface of the tanks – is removed by large scrappers and pushed to the centre of the cylindrical tanks, and later pumped out of the tanks for further treatment. The remaining water is then pumped for secondary treatment (also called biological process).

Biological Treatment Processes

Biological treatment processes (also known as the activated sludge process) are systems that use microorganisms to degrade organic contaminants from wastewater. Air is pumped into aeration tanks that mix the wastewater with the microorganism, causing bacteria and other microbes to spread and consume the remaining organic matter. The microorganisms metabolise nutrients, colloids, and dissolved organic matter, which results in treated wastewater. Excess microbes are removed from the treated wastewater by physical processes. This process leads to the production of large particles that settle down at the bottom of the tanks (biological sludge).

Bio-solids handling

The solid matter that settles out after the primary and secondary treatment stages is directed to digesters. The digesters are heated at room temperature. The solid wastes are then treated where they undergo anaerobic digestion. During this process, methane gases are produced and there is a formation of nutrient-rich bio-solids that are recycled and de-watered into local firms. The methane gas, a by-product of the bio-solids handling, is usually used as a source of energy at the treatment plants. It can be used to produce electricity in engines or to simply drive plant equipment. This gas can also be used in boilers to generate heat for digesters.

Tertiary treatment

The tertiary treatment stage has the ability to remove up to 99 percent of the impurities from the wastewater. Treatment depends on the end use of the water (drinking, agriculture, industry, etc.). This produces effluent water that almost has the quality of drinking water. Unfortunately, this process tends to be a bit expensive as it requires special equipment, chemicals, steady energy supply, and well trained and highly skilled equipment operators.

Disinfection

After the physical/chemical and biological processes, there are still microorganisms in the remaining treated wastewater. To eliminate them, the wastewater must be disinfected in tanks that contain a mixture of chlorine and sodium hypochlorite. The effluent (treated wastewater) is later released into the environment through the local waterways. This water may now be used in industries, for irrigation, and other purposes.

Source: https://pixabay.com/images/search/wastewater%20treatment%20plant/

Deutsch

Deutsch Español

Español Italiano

Italiano Nederlands

Nederlands Polski

Polski Română

Română