Case Studies

We present here 3 case studies of entrepreneurs and start-ups. The case studies presented here have been selected based on their innovativeness and technology they use, circularity, replicability, degree of impact, and coverage. In each case study, we highlight the main challenges and possible solutions.

Case study no.1: From waste water to agricultural water – an innovative technology for combining treatment and reuse in agriculture

Challenge

As we mentioned above, agriculture is by far the largest consumer of water. The use of treated wastewater for irrigation in agriculture can replace agricultural demand and reduce local water stress. On the other hand, the future agricultural development strategies of most developing countries depend on the possibility of maintaining, improving, and expanding irrigated agriculture.

In RichWater project, a group of small start-up companies put together their knowledge to create an integrated approach to combining treatment and irrigation in a single system that can take maximum advantage of nutrients. Their ambition is to develop an up-scaled commercial prototype in South Spain to reuse local community wastewater for irrigation purposes. The aim is to create a win-win situation for two sectors (the wastewater treatment and the agricultural sector) by turning public wastewater into a valuable end-product.

The integrated system consists of a low-cost and energy-efficient MBR (membrane bioreactor) that produces pathogen-free and nutrient rich irrigation water.

The treatment system is connected to:

- The mixing module (for tailor-made mixing with freshwater and additional fertilizers)

- The fertigation unit

- A monitoring/control module including soil sensors to guarantee demand-driven and case sensitive fertigation.

By combining these modules, a complete and turnkey system for safe wastewater reuse in agriculture is available.

Results

- Production of treated wastewater (i.e. reclaimed water),

- Low energy consumption

- Irrigation of 3 target crops at experimental field: tomato, mango and avocado,

- Treated water supplying 50% of main macronutrients (N,P,K) to the target crops,

- Agronomic studies to compare crops irrigated with wastewater and conventional water.

- Cost benefit analysis and feasibility study,

- Market strategy.

Lessons learned

The use of the principles of circular economy have demonstrated that reclaimed water can be used for irrigation supplying. At the same time can provide with 50% of main macronutrients (N, P, K) to the target crops. Although the initial investments are high, energy consumption is low and still results in net economic benefit.

Source: https://richwater.eu/gallery/

Case study no.2: An advanced wastewater treatment technology for the removal of hazardous organic contaminants

Challenge

Endocrine disruptors can be found in birth-control pills, cosmetics, washing powder and many other products normally used in households. Discharging endocrine disruptors into the nature and subsequently into wastewater makes fish, roaches, and snails intersex. The feminisation of fish has been lately noted in Denmark and other places. To prevent the discharge of such Endocrine disruptors from WWTPs outlets to the nature, a cost-efficient method is needed. A group of small companies worked together to develop a system that would make able to eliminate pathogenic microorganisms and endocrine disruptors from wastewater.

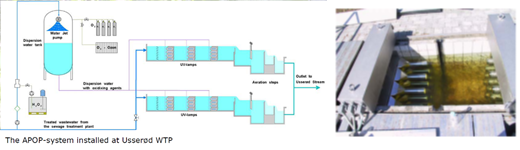

The basic idea is to introduce advanced photo oxidation processes at wastewater treatment plants by using ultraviolet lamps. The light from ultraviolet lamps is able to destroy bacteria and remove chemical substances from wastewater with use of oxidants, e.g. ozone or chloride dioxide.

That way, WTTPs would be able to produce non-hazardous effluent. Characteristics of the method are:

- Simple system for disinfection of wastewater,

- Simple system for removal of endocrine disruptors and other hazardous compounds,

- Flexible system,

- Easy to install,

- Advanced process control technology,

- UV-lamps with high energy intensity,

- Low capital cost

- Low operational cost,

- Environment and health,

- Excellent bathing quality,

- No risks for recipient water fauna and eco-systems,

Results

- Disinfection: This system has demonstrated that it is possible to ensure that effluent from wastewater treatment plants is free of pathogenic microorganisms, guarantee the quality of, and comply with the EC Directive for bathing water.

- Removal of Endocrine Disruptors: The system is useful for removal of endocrine disruptors and other hazardous compounds from treated wastewater (removal rate of 99.8%).

Lessons learned

The technical solution proposed has demonstrated that with a low capital it is possible to meet the requirements of the EU Bathing Water Directive and ensure levels of endocrine disruptors with estrogenic activity in wastewater are low. This experience creates opportunities for entrepreneurs and start-ups to implement other technical solutions based on the end use of water to eliminate water pollutants.

Figure: APOP System.

Source: https://www.slideshare.net/NIDHISRIVASTAVA52/advanced-photo-catalytic-oxidationwastewater

Case study no.3: Water Saving Processes for textile Production

Challenge

Water is an important resource in manufacturing processes, including the textile sector. The textile industry is dependent on water in practically all steps of manufacturing. Dyes, speciality and finishing chemicals used to produce clothing are all applied to fabrics in water baths. This means that huge amounts of water are used to dye, finish, and wash clothes. Reducing water consumption by establishing sustainable production processes can therefore be an advantage for companies as well as the communities in which they operate. In response to water usage and pollution by the textile industry, many corporations have begun investigating alternative solutions.

Here we present a case study of the water conservation measures in dyeing equipment in a textile factory in Croatia. Young entrepreneurs analysed all the processes and selected the best actions to reduce water consumption in the company. They focused on the washing and rinsing processes, as both processes are important in the textile industries to reduce impurities in the fabric to predetermined levels. To decrease the consumption of water in these processes, successful batch and continuous water reduction methods were found. The equipment used in a water conservation programme is relatively inexpensive; in most cases, some valves, pipes, small pumps, and tanks will suffice. The operating costs of these systems are generally very low. Routine maintenance and, in some cases, electricity for the pumps, could be more expensive. Water conservation measures lead to [33]:

- Reduction in processing cost,

- Reduction in wastewater treatment cost,

- Reduction in thermal energy consumption,

- Reduction in electrical energy consumption,

- Reduction in pollutants load.

Results

The application of these measures allowed significant savings in the water itself (90% of the water), as well as the costs associated with its discharge and the inlet water.

These integrative techniques can be implemented in other textile industries. The payback period for a water conservation system will vary with the quantity of water saved, sewer fees, and costs for raw water and wastewater treatment.

Lessons learned

Water conservation and reuse is a necessity for textile industry. It is possible to reduce the quantity of water used in the textile factories. It lowers the cost of finished textile products by lowering charges for fresh water and sewer discharge. The quantity of water required for textile processing varies from factory to factory and depends on fabric produce, process, equipment type, and dyestuff. That creates many opportunities for entrepreneurs and start-ups adapt their water consumption to their own textile businesses.

Deutsch

Deutsch Español

Español Italiano

Italiano Nederlands

Nederlands Polski

Polski Română

Română