Casestudy’s

Case study no.1: Energy Academy Building

Energy is an important industry in the world economy as well as in the Dutch economy. The Netherlands is one of the world’s top eight gas producers, and one of the top two in Europe [21]. Since the 1950s, energy has been at the heart of economic development and knowledge-based activity in the Northern Netherlands [21]. In the fields of gas, steady power supply, and the integration of renewable energy into the energy distribution chain, the region plays a leading role.

The Energy Academy Europe, a new institute in the Netherlands where education, science and business collaborate on energy research and innovation, aspired to build on these strengths within existing business and knowledge infrastructures in order to become an international hotspot in the field of energy education entrepreneurship, innovation and research. The Energy Academy Europe’s goal is to make a substantial contribution to the energy transition in order to assist and expedite the transition to a more sustainable energy future [21].

The building has a unique design with a big solar roof to accomplish the sustainable energy principles. The almost 15.000 square meters building was completed in October 2016 in the Zernike Campus in Groningen and received a BREEAM rating of ‘Outstanding’ [22].

The new structure is intended to encourage people to collaborate, share ideas, be creative, and produce energy. The innovative design illustrates how a structure may make the most of natural resources such as soil, water, air, and sunshine as a major source of energy. Its roof is covered with solar panels which are used to capture solar energy to its maximum potential. The solar panels provide not only electricity, but they are also arranged to ensure maximum natural illumination. This outer layer provides the building a distinctive look, calling attention to the building’s revolutionary energy management system [23].

The Energy Academy Europe is a place for entrepreneurs, professionals, students and researchers from the Netherlands and around the world to collaborate, inspire, and – most importantly – stimulate the development of a more suitable and sustainable international energy supply for future generations.

Source: https://www.pinterest.com/pin/409827634835087558/

Case study no.2: EnTranCe

The Centre of Expertise Energy, or EnTranCe, is an initiative from the north of the Netherlands that helps to accelerate the transition to clean, renewable, and cost-effective energy. The expertise centre brings together scientists, students, entrepreneurs, corporations, governments, and social institutions to exchange their knowledge and work towards making breakthroughs in the topic of energy transition as well as enhancing the regional knowledge economy [56].

EnTranCe is a public-private collaboration that allows for open knowledge exchange. The notion of open innovation is being implemented here, with innovative ideas being shared with businesses, government agencies, and social organisations. EnTranCe accelerates the energy transition and improves the knowledge economy in the north of the Netherlands through promoting innovation.

EnTranCe’s energy study is primarily focused on towns, districts, neighbourhoods, and businesses. This is the point at which large-scale energy providers and infrastructure collide with small-scale, local energy efforts in order to enable a smooth transition to a stable renewable energy source [56].

Source: https://nl.linkedin.com/company/entrance-centre-of-expertise-energy

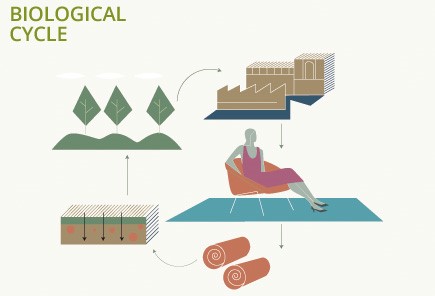

Case study no.3: Climatex LifeCycle “Waste Equals Food”

According to the Cradle-to-Cradle framework, products should be developed to regenerate the environment as biological nutrients or to revive industries as technological nutrients. Rohner Textil (now owned by DesignTex) worked with William McDonough and Michael Braungart to create a fully biodegradable cloth that can be used in the garden after usage [69].

Due to the problematic colours used in the product, product leftovers were formerly classified as hazardous waste in Switzerland. Using the Cradle-to-Cradle philosophy of “waste equals food,” McDonough and Braungart looked for materials that were “safe enough to eat” to use in the fabric [69]. Therefore, they demanded the complete component composition from suppliers in order to determine their level of healthiness. As a result, only one supplier (Ciba-Geigy) agreed to disclose its proprietary dye compositions. From these only 16 nontoxic colours were chosen for the fabric line rebuilding out of hundreds of chemicals evaluated [69].

The fabric resulted from this is called Climatex® LifeCycleTM and is made entirely of natural fibres such as wool and ramie, as well as nontoxic dyes. Regarding leftovers, they are crushed into a felt-like material and sold as mulch to local farmers and gardeners instead of going to the landfill.

Climatex Lifecycle accounted for a third of Rohner’s $8 million in revenues by 2002. Rohner Textil’s waste disposal expenses were substantially lowered since he no longer had to pay to ship trimmings to Spain as hazardous waste, or to have them burnt in a Swiss-approved incinerator, or to have them recycled [69]. By reducing the dye list and eliminating the requirement for dye filtration, overall manufacturing costs were reduced.

Source: https://www.climatex.com/en/sustainability/cradle-to-cradle/

Deutsch

Deutsch Español

Español Italiano

Italiano Nederlands

Nederlands Polski

Polski Română

Română